Description

It is installed on fishing vessels with an unlimited navigation area and large coastal fish processing enterprises. The installation is manufactured in a climatic version: OM category 5 according to GOST 15150-69 during delivery to ships; In category 3 according to GOST 15150-69 during delivery to coastal enterprises. To improve the quality of cooking fish raw materials, a cooker with a thin layer of cooking raw materials is installed in RMU-80. And for efficient flour drying, a rotary-tube type dryer with a heated air flow injection system and a rotary disk type dryer are used, which allows to obtain higher quality feed flour and, in turn, reduces the cost of finished products.

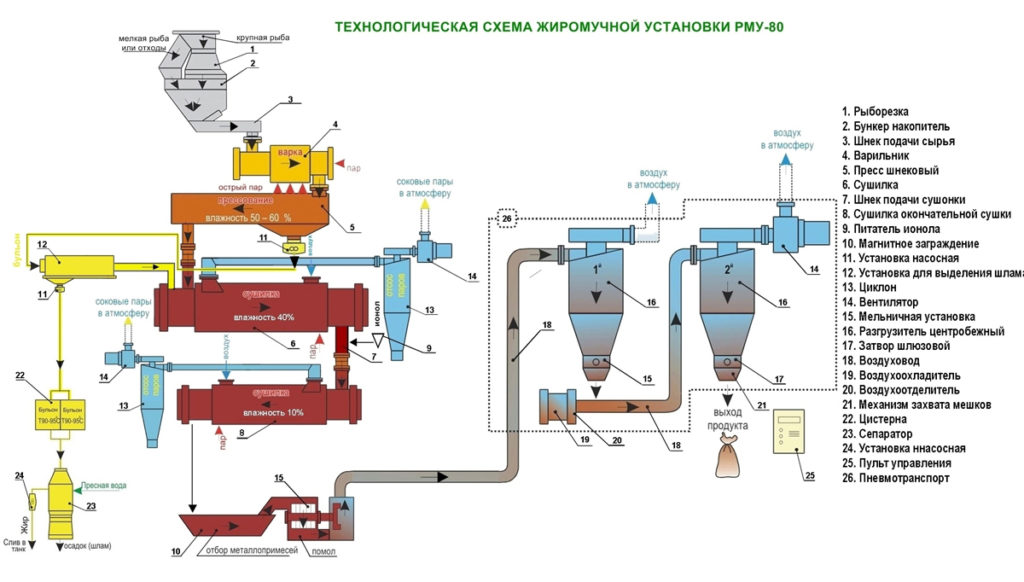

Working principle:

Small fish enter the storage hopper (2), large fish enter the hopper through the fish cutter (1). From the hopper, the fish is fed by an auger (3) into the digester (4). In the digester, the raw material is steamed, mixed and moved forward by an auger. From the digester, the boiled mass enters the twin-screw press (5), where the liquid fractions of fat and broth are separated. The selected fractions are pumped by the pumping unit (11) to the sludge separation unit (12). The suspended particles separated in the sludge separation unit are fed to the dryer by an auger. The pressed mass from the press (5) enters the rotary-tubular dryer (6), where preliminary drying takes place. Drying is carried out due to the contact of the pulp with steam-heated surfaces of the tubular shaft and the body of the dryer (6). Evaporated moisture is removed by air passing through the dryer, which moves in the opposite direction to the movement of the material. The air that passed through the dryer (6) enters the cyclone (13), where flour dust is separated from it. After preliminary drying with an auger (7), the drying is sent for final drying in a dryer (8). After drying, the raw material in the form of large flour (dried) falls into a magnetic barrier (10), designed to catch metal impurities in the drying process. From the ionol feeder (9), the antioxidant enters the drying supply auger (7). From the hopper, the magnetic drying barrier is sucked into the mill unit (15), where it is crushed and pumped into the 1st centrifugal unloader (16). From the 1st unloader, the flour enters the duct, where it is cooled by air from the cooler (19) and through the 2nd centrifugal unloader (16) and sluice gate (17) it enters the package. The clarified broth from the sludge separation unit (12) enters the 1st compartment of the tank (22), is heated to a temperature of 90-950C and flows by gravity into the separator (23) for the separation of fish oil. As the broth is filled, heated and fed to the separator, the tank compartments work alternately. The fat separated on the separator is fed into the ship’s tank by an electric pump unit (24). Defatted broth is disposed of or poured overboard.